puf Panel

polyurethane sandwich panel , shor for PU sandwich panel, also named as PUF panel

- Double side:0.3-0.75mm PPGI or Alu. sheet

- painting:PE/SMP/PVDF/HDP/ Painting

- Warranty: 10-25 years Auti-rust

- Color:based on Ral or your swatch

- Core Material :40-45kgs/m3 PU

- Cover width for wall:950/1000mm

- Thickness:40/50/60/75/100/150/200mm

- Anti-fire Grade:B1,B2,B3

- Anti-water Grade:best

- U-value(w/m2k) 100mm roof:0.22

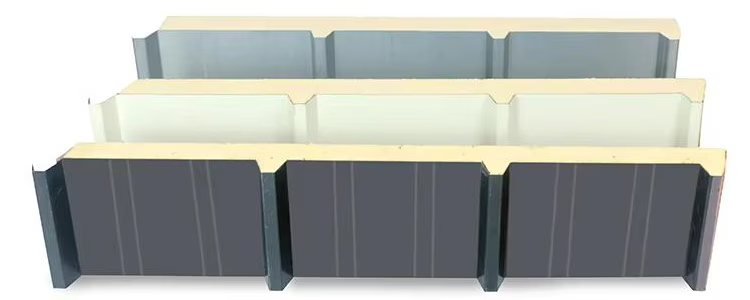

- Locking system for wall:Hidden or groove&T

- Locking system for roofing:Hidden

production description

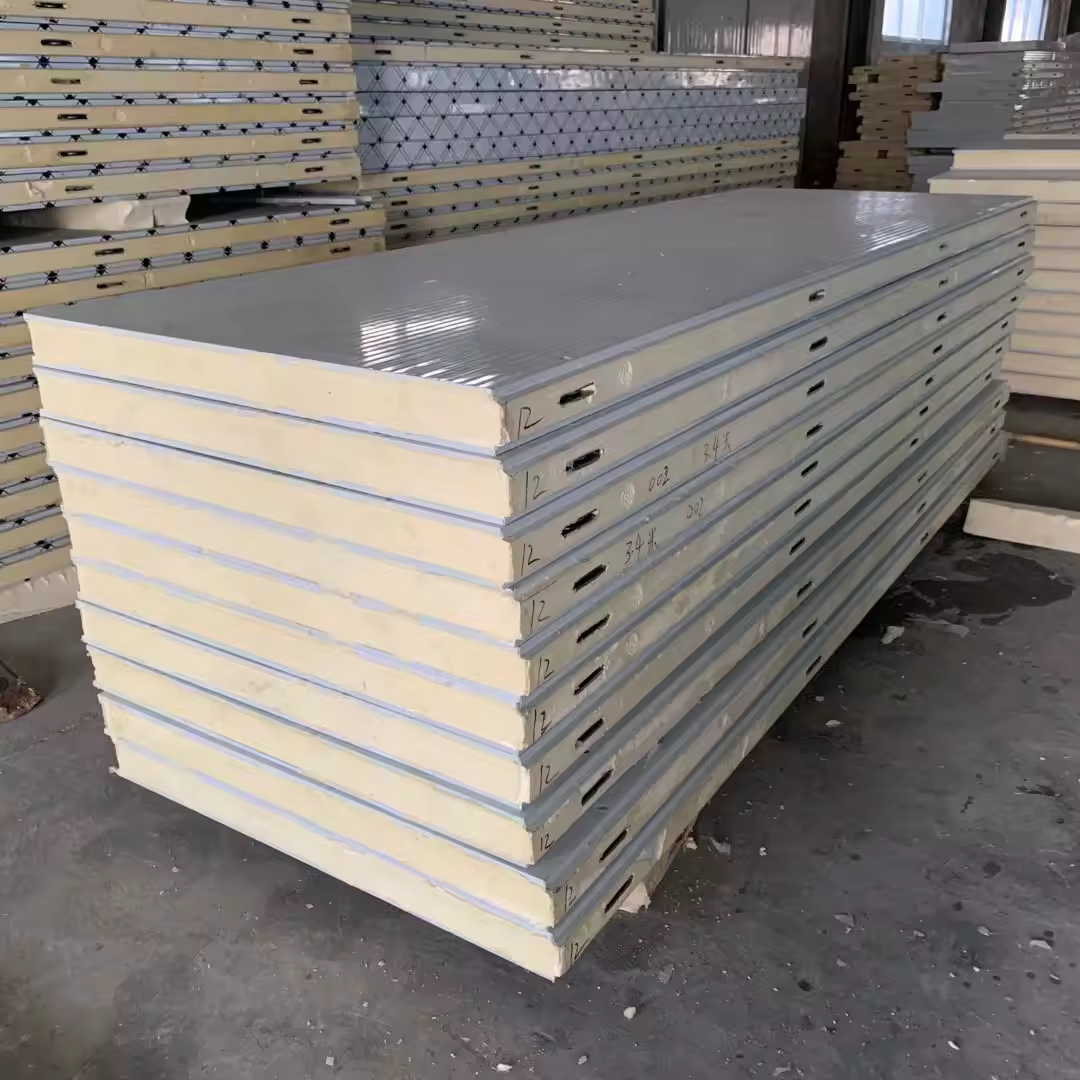

The Polyurethane Sandwich Panel, also known as PU or PUF panel, features high-quality color-coated steel sheets as its top and bottom surfaces. Its core material consists of polyurethane, bonded through high-temperature curing foaming and double tracking. This construction ensures excellent thermal insulation, bending resistance, and sound insulation properties.

Additionally, the panel is fireproof, offering high strength with a novel and exquisite appearance, making it the preferred choice for many large-scale facilities.

The thickness can be customized, 50mm PUF panel ,60mm PUF panel ,100mm PUF panel,150mm PUF panel.

Our materials offer Grade B combustion performance, with a maximum operating temperature of 180°C (250°C for instant elbows). They undergo carbon formation directly under flame exposure, without dripping, curling, or melting. Post-flame exposure, a protective “Graphite Foam” layer forms on the surface, effectively safeguarding the underlying foam structure.

Experience exceptional thermal, heat, and sound insulation with our advanced materials. Our 35 mm thick air-cooled panels offer anti-condensation performance equivalent to a 1130 mm thick traditional red brick wall.

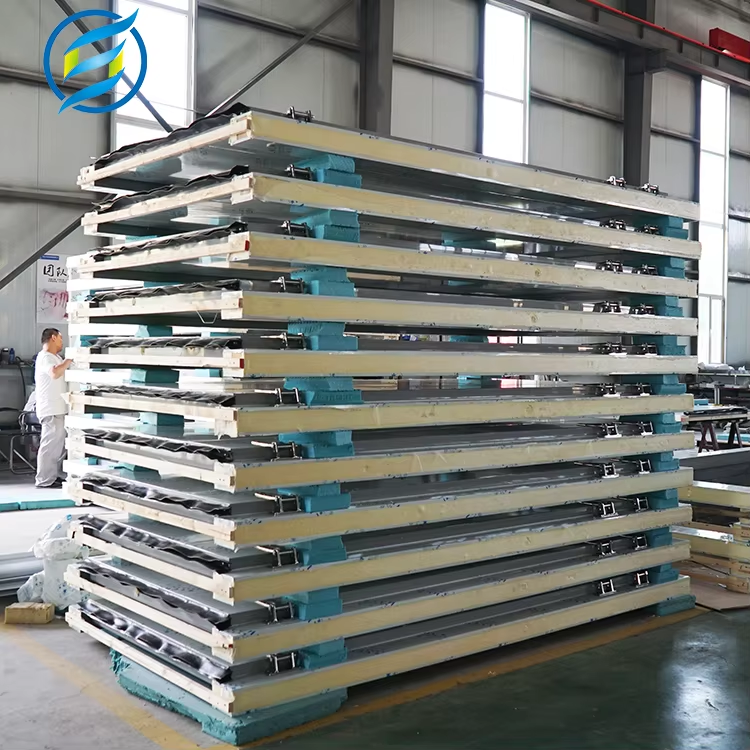

Benefit from high levels of prefabrication and assembly, minimizing construction delays due to adverse weather conditions. Compared to traditional methods, our streamlined approach can reduce construction timelines by over 40%.

Discover the allure of lightweight, elegantly shaped materials designed for structural brilliance. With a density ranging from 10 kg/m² to 14 kg/m², these materials are approximately 1/30th the weight of traditional building walls. Their minimalist surface, devoid of unnecessary embellishments, offers a timeless aesthetic.

These materials excel in strength, stiffness, stability, washout resistance, shock resistance, and durability against corrosion and atmospheric conditions. They are ideal for load-bearing structures, eliminating the need for additional beams and columns in many applications.

The difference between EPS panel, XPS panel and Polyurethane panel:

PUF Panel system for wall

Thermal Insulation Performance: Polyurethane sandwich panels excel in thermal insulation among similar materials. They achieve equivalent energy savings with thinner insulation boards, enhancing system stability.

Thermal Stability: Rigid foam polyurethane exhibits superior thermal stability, withstanding temperatures up to 120°C compared to polystyrene’s 70°C. This reduces the risk of secondary foaming and seam cracking in benzene boards at higher temperatures.

Combustion Principle: Polyurethane, a thermosetting material, forms a protective carbonized layer when heated, inhibiting heat and oxygen penetration to prevent combustion spread. In contrast, thermoplastic polystyrene shrinks, melts, drips, and burns without forming a barrier layer, requiring flame retardants for fire safety.

Application Scope: Polyurethane foam offers diverse application methods—spraying, pouring, and factory foaming—making it more versatile than factory-molded polystyrene foam.

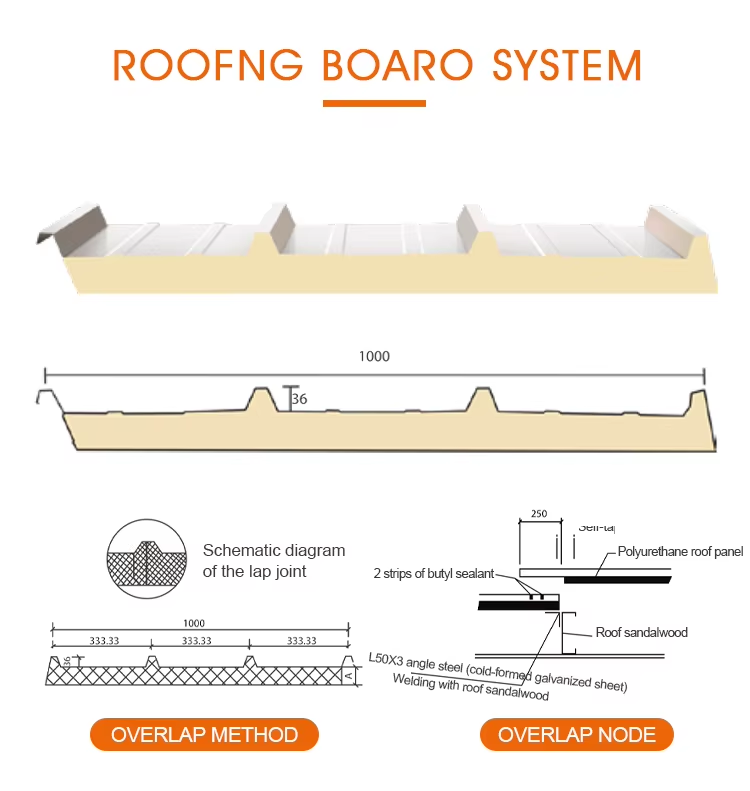

PUF panel system for roof

Features/Advantages of Roof PUF Panels:

- Fire Resistance and Heat Insulation: The roof panel offers excellent fire resistance, heat insulation, and air tightness.

- Lap Structure with Embedded Air Ports: Air ports between panels are embedded in a lap structure, utilizing hidden screw technology for rapid, leak-free roof construction.

- Energy-efficient Building Envelope: It serves as an energy-saving building envelope with superior performance.

- Large Reinforcing Rib Design: Surface design includes large reinforcing ribs that enhance span space and reduce structural costs.

- Lightweight and Cost-effective: As a lightweight roofing material, it saves on both structural and installation expenses.

We are a manufacturing plant. You are welcome to visit us at any time. The workshop has a complete advanced steel structure, steel plate production equipment system. So we can guarantee good quality and competitive price.

Acceptable delivery methods :CIF,FOB,EXW. Accepted payment currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, RMB. Payment methods accepted: Telegraphic transfer, L/C, credit card, PayPal, Western Union.

Of course. We can produce according to customer’s requirements.

Delivery times depend on the size and number of buildings. Generally within 30 days after receiving the payment. Partial shipment is allowed for large orders.

Delivery times depend on the size and number of buildings. Generally within 30 days after receiving the payment. Partial shipment is allowed for large orders.

Our free sample policy:

If you need one, let us know the detaied specifics, such as what kind of panel,and contact us by [email protected]