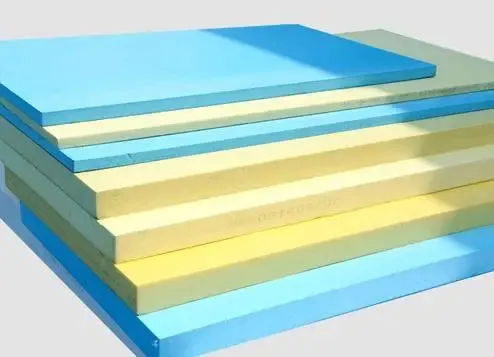

Comparison of EPS and XPS Insulation Boards: Differences in Properties and Applications

- Production Process and Density:

- EPS Boards: These are made by expanding polystyrene beads in a heated mold, resulting in a foam material. EPS boards typically have a lower density, ranging from 15-35 kg/m³, and offer good thermal insulation properties.

- XPS Boards: These are made by adding specific additives to polystyrene beads and then extruding them under high temperature and pressure. XPS boards have a higher density, usually between 28-45 kg/m³, and possess better compressive strength and a closed-cell structure, which enhances their water resistance.

- Compressive Strength:

- EPS Boards: Compared to XPS boards of the same density, EPS boards have lower compressive strength. They are commonly used in applications where load-bearing capacity is not critical, such as external wall insulation or roof insulation.

- XPS Boards: Due to their higher density and closed-cell structure, XPS boards offer superior compressive strength and are suitable for applications where weight-bearing capability is required, such as floor insulation or foundation insulation.

- Thermal Conductivity:

- EPS Boards: Typically, EPS boards have a thermal conductivity ranging from 0.032 to 0.040 W/(m·K), providing good thermal insulation.

- XPS Boards: XPS boards have lower thermal conductivity compared to EPS boards, typically ranging from 0.028 to 0.035 W/(m·K), offering better insulation performance for the same thickness.

- Water Resistance:

- EPS Boards: EPS boards can absorb water over time, although the absorption rate is relatively low (usually below 4%). They require waterproofing measures when used in wet environments.

- XPS Boards: XPS boards have excellent water resistance due to their closed-cell structure, with water absorption rates typically below 1%. They do not require additional waterproofing treatments in most cases.

- Cost:

- EPS Boards: EPS boards generally have a lower cost compared to XPS boards, making them suitable for general building insulation needs.

- XPS Boards: Due to their manufacturing process and performance advantages, XPS boards are typically more expensive. They are chosen for projects requiring higher insulation performance and durability.

In summary, the choice between EPS and XPS boards depends on specific building project requirements, including environmental conditions, insulation needs, load-bearing requirements, and budget considerations.